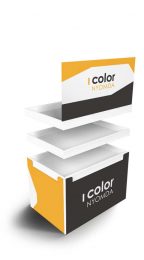

Display manufacturing

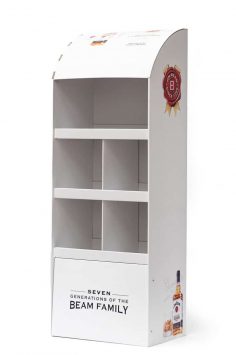

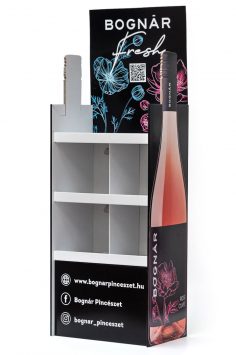

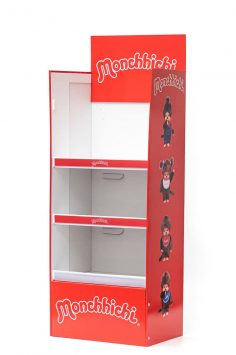

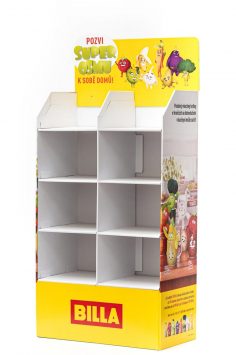

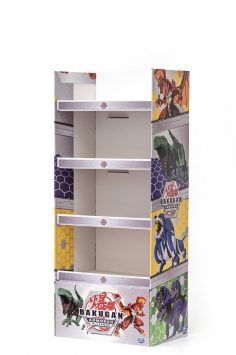

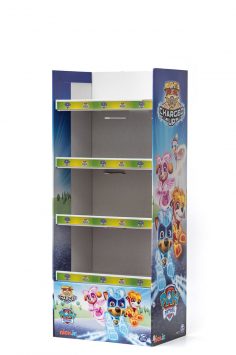

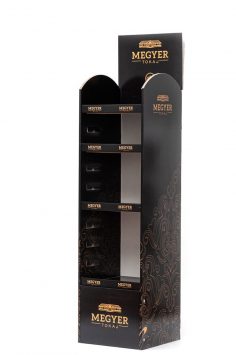

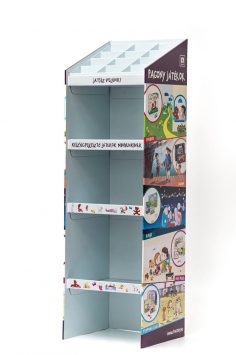

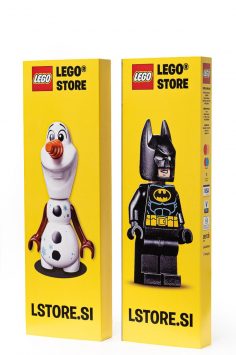

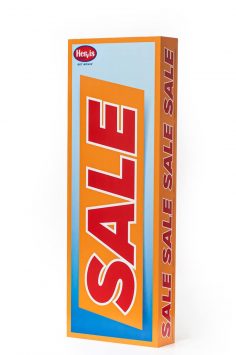

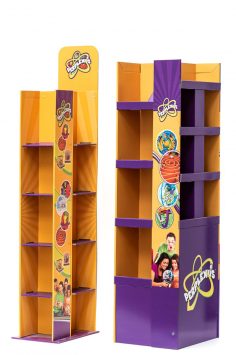

The displays are excellent means for popularizing various products, visually presenting special offers and individual proposals in style, in line with the profile.

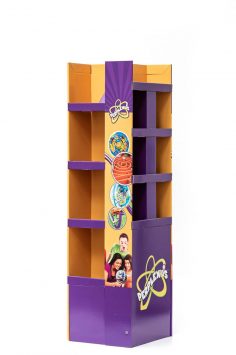

A display can be spectacular as a standalone shop furniture but can stand up even on exhibition stands or as supplementary decoration element on conferences.

What are the features of a good display?

They can be used as product display when introducing new products or for advertising cultural events, business events and other special marketing purposes.

The efficiency of the display can be increased by:

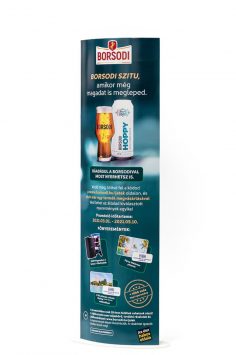

- Variability (regarding for example placement),

- High-quality printing (lifelike, vivid colors, optimal color depth),

- Personalized graphics and design,

- Unique design and manufacturing parameters.

Standard display típusok

Egyedi display típusok

Metal display

Wooden display

What does our print shop needs to complete your display order?

To the exact creation of your display according to the design please send the image materials prepared ready to print according to size and distribution of the ordered item(s) in a minimum resolution of 300 dpi as a composite PDF file in CMYK color model.

Display manufacturing guide

What is corrugated carton or professionally correctly corrugated paperboard, in short CPB?

If you have seen product placement on shelves made of paper, that is, display in any shop or technical product packaging, transport box, then you are likely to know the corrugated carton.

Is is almost impossible to live your everyday life without constantly encountering products made of corrugated paperboard.

Do you know those elements which define how strong – or how expensive – is the corrugated carton?

What is it manufactured from?

And how they impact the price-to-value ratio or functionality of the packaging?

In our corrugated carton (corrugated paperboard – CPB) guide we try to explain everything from the quality of the corrugated carton through the carton types to the possible mode of use.

Learn everything about the key components of the corrugated carton and how they influence for example the costs and the load capacity.

From the flute to the gram weiht, from the coating to the number of walls we try to explain everything.

Composition of the material

How is the corrugated material formed?

Before entering into the more detailed technical details, it is worth highlighting the method of the formation of the corrugated carton.

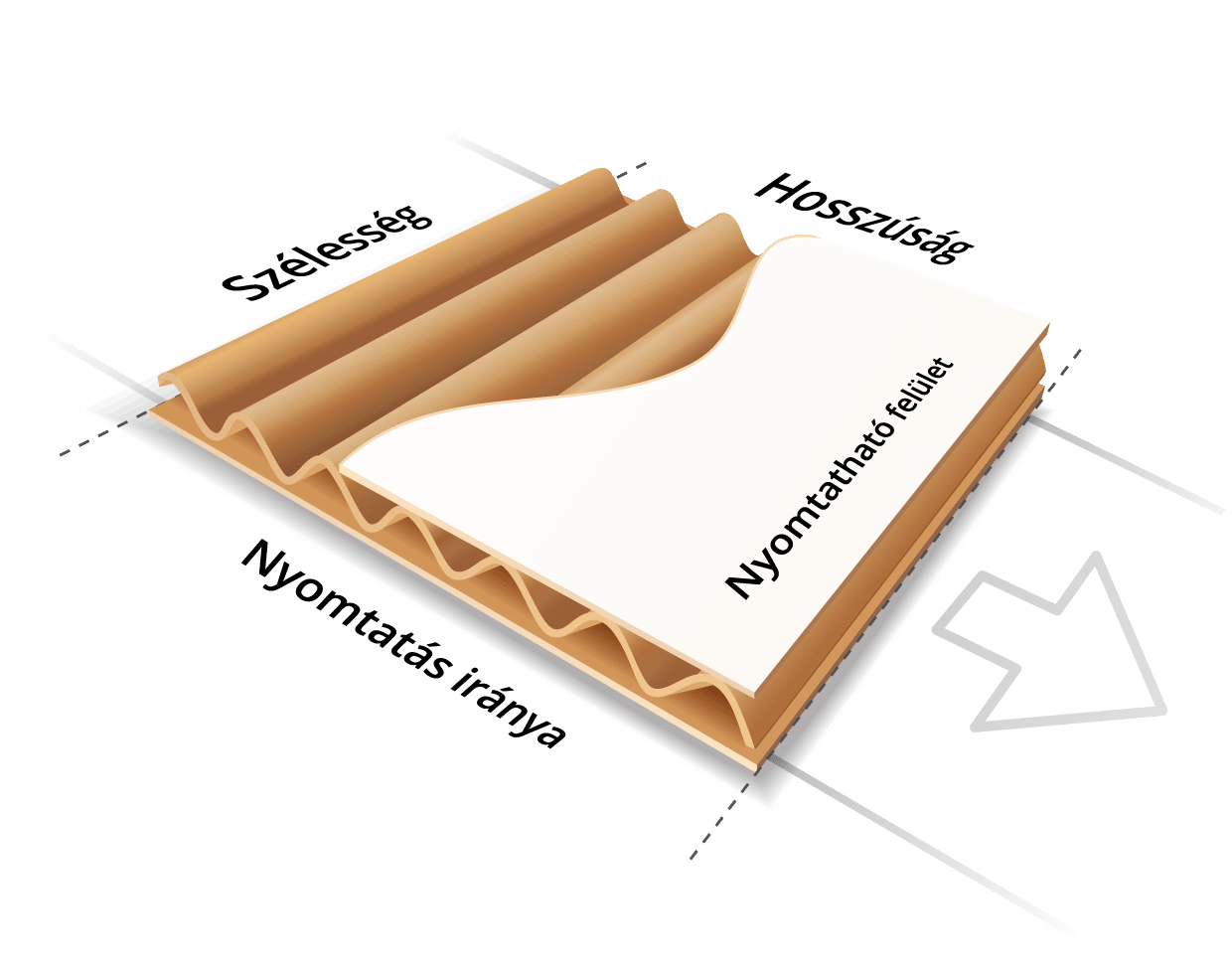

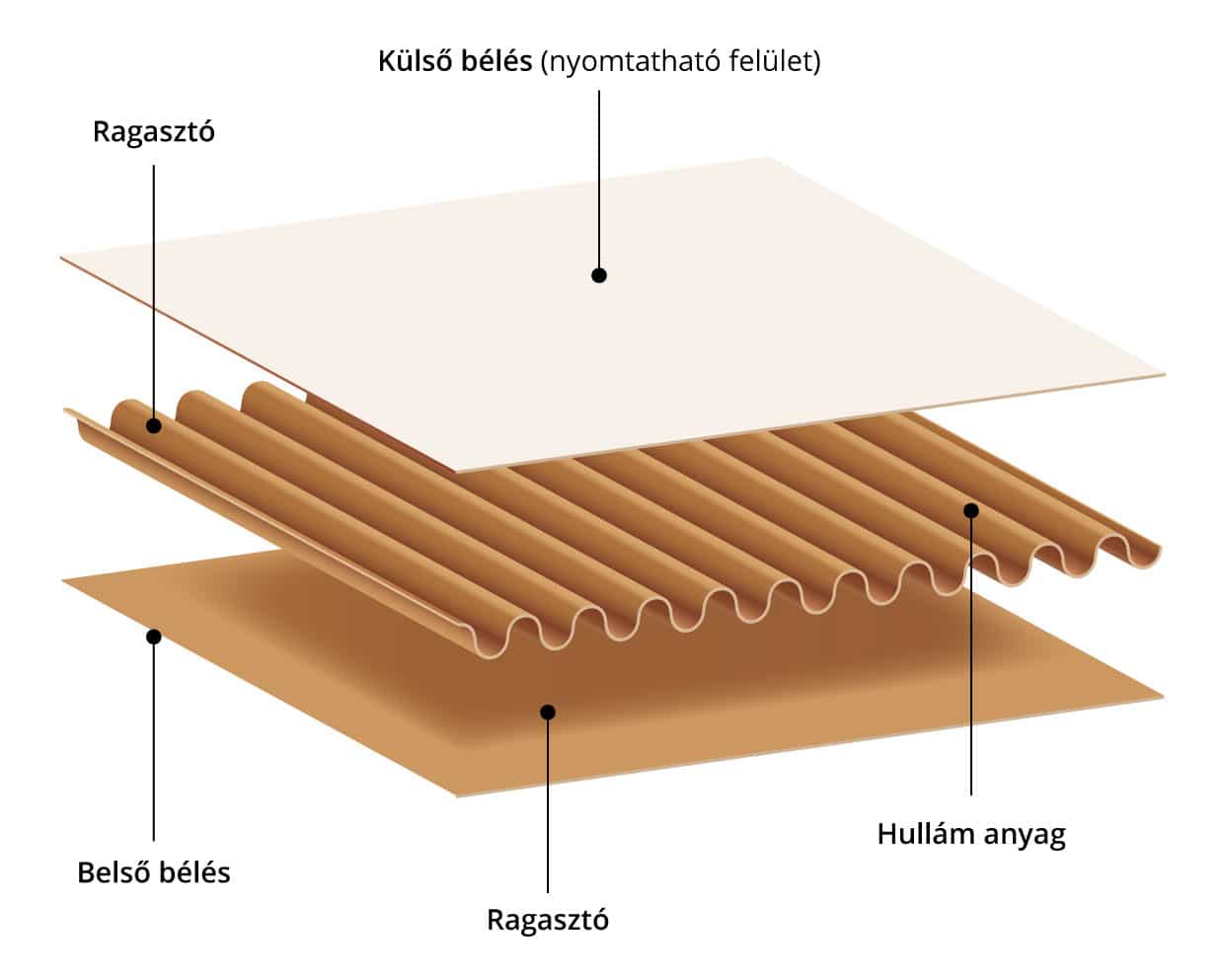

A corrugated paperboard is usually made of three layers.

It is made of material fluted in the middle or “corrugated”:

From 2 external paper layers (external and internal coating) between which there is a corrugated paper layer.

Both sides of the corrugated paper are glued to the flat paper coating during manufacturing.

The glue fixes the flutes, provides rigidity and stability to the carton.

Paper types

Material used for manufacturing of the carton

The most important factor which determines the properties of the corrugated carton is the type of the paper used.

Despite the wide-spread expansion of the cartons, two main types of paper exist which are usually used for the lining.

These are known as Kraft and Testliner.

Also available the Schrenz which is made exclusively of recycled paper.

Kraft paper

Kraft paper is made of softwood.

Due to the “virgin fibres” this is the strongest paper and also the easiest to print.

Due to these properties of it it is the most frequently used external base material used to manufacture corrugated carton boxes and packaging.

Testliner

The testliner is actually a dual-layer (or duplex) paper.

Since it is recycled, the Testliner is not so strong as the Kraft and it is more difficult to print on it, so it is used usually on the internal side.

Its price is much more favorable than that of the Kraft paper.

All types of linings consist of two separate layers.

A base layer is applied for the adhesion and rigidity while a finer “coating layer” is applied mainly for the improvement of aesthetic and to make printing easier.

Despite the Kraft and the Testliner being the most popular, actually several other options exist.

The paper quality available for the external and internal lining during the manufacturing of the carton is the following:

KRAFT (K): “Virgin” Kraft paper

Testliner 2 (T2): Partially recycled

Testliner 3 (T): Fully recycled

CHIP (C): Waste-based linings

Fully bleached (BW): Fully bleached Kraft lining

White coating (WT): White coating recycled lining

„Patched” Kraft (MK): Patched white Kraft

Oyster (OY): Patched Testliner

Semi Chem (SC): Virgin fibres with sulphite chemical process

Waste-based (WB) 100% recycled fibres

The last two paper types listed here is used most often for flutes, less often for linings.

Paper weight, that is the grammage

After describing the generally used paper types available , it is important to understand also the weight of the paper.

This is measured identically for all types of papers: taking one square metre from the given paper and measuring it yields the grammage for this paper for one square metre.

Thus if using corrugated board with a Kraft paper lining of 125 g/m2, it often can be seen as 125K.

The grammages used most often for corrugated carton:

115/125 g/m2

140/150 g/m2

185/200 g/m2

300 g/m2

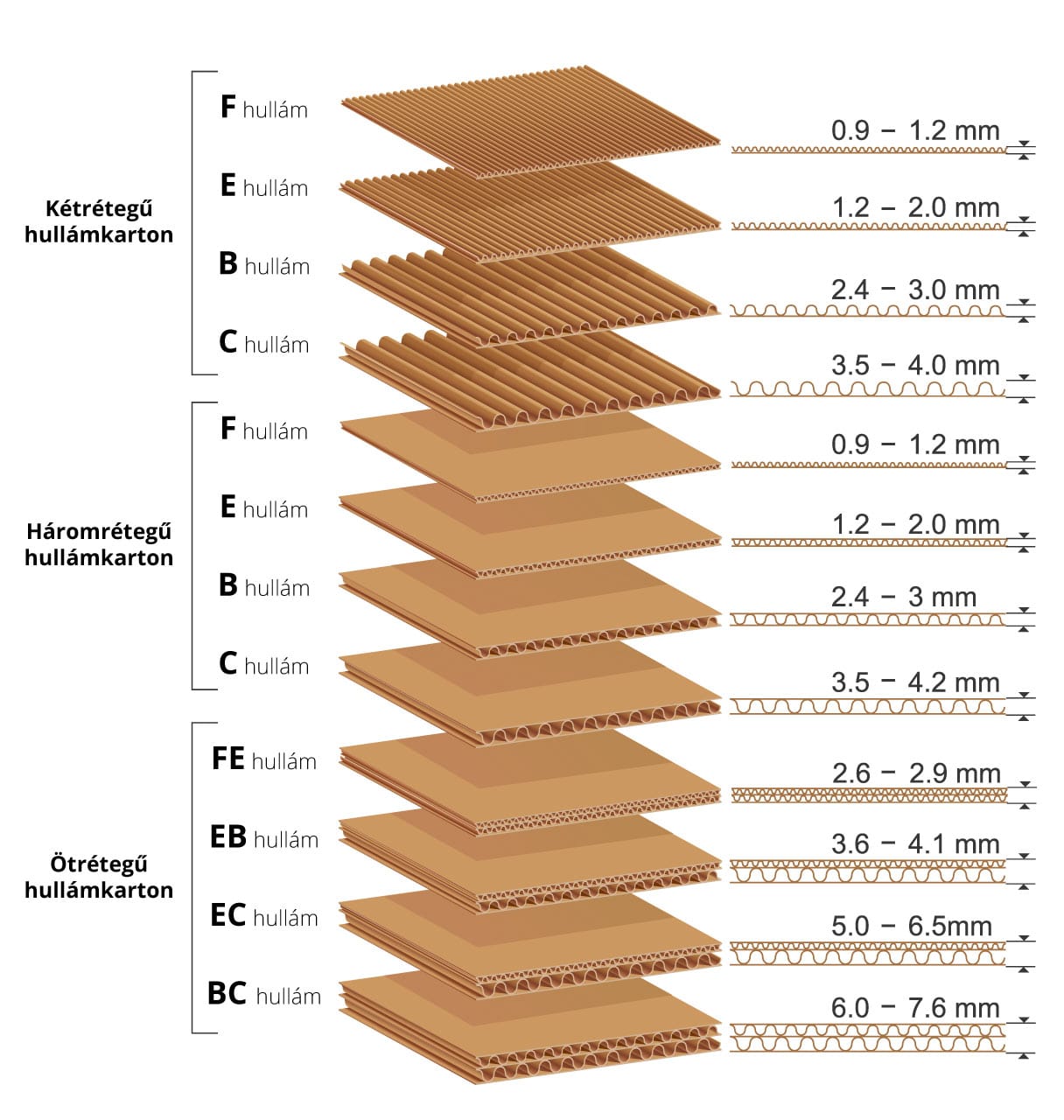

Corrugated carton types

Composition of the material of the corrugated carton

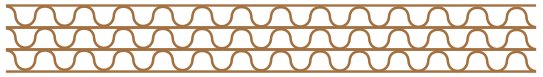

An additional corrugated layer and an additional lining can be added to produce the so-called five-layer carton.

Practically, this provides extra rigidity and durabilty, making it suitable for packaging heavier objects and providing additional protection for the possibly more delicate or expensive objects.

An example can be seen below.

Five-layer or dual-wall corrugated carton

In addition to the variable paper weights and types the type (and number) of flutes is also to be taken into account.

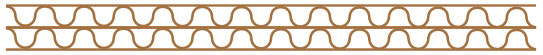

At basic level the corrugated carton consists of the two linings and the one flute.

This is called triple-layer corrugated carton.

Triple-layer simple corrugated carton

If your transported goods are particularly heavy or large (for example automotive parts, industrial equipment, etc.), seven-layer carton can also be used.

As its name suggests, this adds a new stage to the flute and the lining, strengthening it even more.

Seven-layer corrugated carton

A „flutes”

Explaining flutes

The last criterion of the corrugated carton which can affect its performance (and its weight and cost) is the type of the flute.

The flute is the “ribbed” section between the two linings and changing its height (thus the size of flutes) different performance characteristics can be achieved.

This may vary from the very fine fluting, for example the manufacturing of “E” light retail cartons (it is very good to print on it) to the rougher flutes for example “A” or “B” which are used only for the packaging of transit goods.

Similarly to the examples above, with a triple-layer material one or more flutes can be combined to create such class as the “EB or “BC flute.

This offers a rigid structure which is perfect for heavier objects and at the same time it improves the aesthetic external appearance and printing surface.

BC corrugated carton

There are several generally used flute profile, these are as follows:

Name of corrugated carton types

The information already known enable the creation of an abbreviation which describes the type of the carton used.

For example if the material quality specifies a 125 g Kraft external lining, a 125 g Testliner internal lining and a B-flute, it is described as follows:

125K / B / 125T

Similarly, a 150 g Testliner external lining and a 150 g Testliner internal coating with E flute can be described briefly:

150T / E / 150T

Applications

The mere knowledge of the manufacturing of corrugated carton and its components not necessarily enables us to make an informed decision on the type of material used for packaging.

The following information provide more details on the most frequently used flute types.

E flute

The thickness of E flute is between 1 mm and 1.5 mm which results in a very fine flute.

This provides not only high crush resistance and break resistance but a printing surface of an excellent quality.

Thanks to this these are usually used for smaller boxes where good quality print is necessary and it is also a good choice for die-cutting.

Corrugated carton type E

B flute

The B flute is the most frequently used carton type which is used for packaging.

3 mm thick, exceptionally versatile and can be used both for die-cutting and other machine cutting processes.

Provides good overall performance for all types of packaging.

Corrugated carton type B

C flute

With thickness between 3.5 mm and 4 mm the C flute offers better crush resistance than the B flute.

This means that it provides better stacking durability for lighter products.

However, in case of inappropriate application it may tend to crush.

Corrugated carton type C

BC flute

The 6-7 mm thick dual-wall material combines the B and C flutes.

This provides good performance for any kind of use and allows the manufacturing of transportation boxes providing better protection.

Usually it receives single-color printout consisting of markings or possibly logo.

Corrugated carton type BC

EB flute

The EB flute of 4-4.5 mm thickness (as its name suggests) unite the E and B flutes.

Due to the use of the very fine (E) and the relatively large (B) flute, this type provides the most excellent balance between the durability and the nice printing surface.

Due to its above characteristic, this is the most frequently chosen material as for display manufacturing.

Corrugated carton type EB

Weights

Since when specifying the carton type required for packaging, there are several variable parameters – for example the weight of the paper, the type of flute and the number of walls, in fact similar performance can be achieved with the quality of the different boards.

There are, however, typical weight guidelines for the different corrugated board qualities which can be regarded as standards.

These are listed in the following table:

| Flute | Type | Weight | ||

| B or E | 125 K/T | 4-6 kg | ||

| B or E | 150 K/T | 8-12 kg | ||

| B or E | 200 K/T | 12-17 kg | ||

| B or E | 200 K/ 300 T | 17-25 kg | ||

| B or E | 300 K/T | 25-35 kg | ||

| BC or EB | 125 K/T | 10-15 kg | ||

| BC or EB | 150 K/T | 15-25 kg | ||

| BC or EB | 200 K/T | 25-35 kg | ||

| BC or EB | 200 K/ 300 T | 35-40 kg | ||

| BC or EB | 300 K/T | 40-45 kg | ||

Terms used during use of corrugated carton

Clay coating – Thin kaolin coating to improve the printing surface of the corrugated carton. Used on unbleached or natural Kraft carton.

Lining – One of the paper materials which forms one of the parts of the components of the corrugated carton. There is an internal and external lining; usually the external is of a better quality because the printing is done on it

Duplex – Consists of two layers, its exterior is often coated, making it more waterproof, often used for paper cups and plates, and in the pharmaceutical industry.

Reinforced flute – Replacement to the standard flute, which strenghtens the material and makes it more durable.

FEFCO – The European Federation of Corrugated Board Manufacturers is a non-profit organisation which represents the interests of the corrugated board industry.

FEFCO codes – The array of the standard planning samples used in the corrugated carton industry.

Patched – Paper lining with off-white appearance.

Grammage – Weight of paper expressed in g/m2 (grams per square-metres).

Triple-layer corrugated carton – Combination of two layers of corrugated material (of potentially different types) for providing extra durable material. Consists of corrugated paper in the middle and of two materials (usually carton) which is fixed to both sides of the corrugated paper.

Back cover insert – Compressible paper material which compensates the possible unevenness of the closed surface. This compressible material is usually glued to the lining and it provides better surface (appearance), waterproofness and extra durability.

Flute cross section – Measurement unit used to measure corrugated carton, the measurement direction is contrary to the flute (width).

Corrugated material – Material shaped into series of parallel crests and grooves.

Corrugated paper – The paper providing the middle layer of the corrugated carton. This separates the linings and provides dirability and rigidity.

Flute profile – The shape of the flutes in the corrugated material.

Light weighting – light weighting in packaging is the forming of such packagings which reduce material consumption, reduce weight and costs and reduce the environmental load as well.

Kraft paper – Paper made from virgin cellulose during pulping. Made of natural, unbleached wood fibres.

Five-layer – triple corrugated board which is used due to its durability, flexibility and ecofriendliness.

Crack, damage – Spllitting or cracking packagings due to too high pressure (for example if stacked on each other, the boxes located on the bottom of the stack may crack, crush).

Edge crush test – The durability test of the corrugated carton against the vertical crush resistance.

Fibre packing materials – Made of moulded fibres, also known as moulded pulp.

Board grade – The classification of corrugated carton according to three elements: first the weight and type of the external lining, second the type of the flute, third the type and weight of the internal lining.

Testliner – Recycled lining board. It is available homogeneous or combination of two layers in such way that the external layer is a recycled sheet of a better quality.

Cracking – An edge crack test measures the transverse cracking of the corrugated board. Provides information on the resilience of the sheet.

Can corrugated carton box be recycled?

The corrugated carton boxes can be found everywhere in today’s business environment.

They were present everywhere but with the expansion of the e-commerce the corrugated carton transport boxes are there at almost every threshold, accumulate in every garage and warehouse.

It is understandable therefore that the increase of the quantity of the boxes raises some questions on the sustainability.

How to get rid of this carton efficiently and minimize its environmental impact? Fortunately most of the corrugated carton boxes are recyclable.

What is corrugated carton made of?

The corrugated board boxes are made of multiple carton layers which are pressed together with a thin, corrugated carton layer to create air chambers. This triple-layer structure makes the corrugated carton boxes durable while remaining light.

The recycling has a central role in the life cycle of the corrugated carton box. Many of the corrugated cartons in everyday use is already being made of recycled corrugated carton. When choosing corrugated carton, you contribute to the spread of one of the most sustainable packaging system of the world.

Recycling of corrugated carton boxes

Apart from some important exception, the corrugated carton boxes are almost always recyclable. As mentioned earlier, the corrugated carton boxes are often made of recycled materials, for example other recycled corrugated carton boxes, therefore, with appropriate disposal, they belong to the more environment friendly packing materials. Actually the corrugated carton belongs to the most often and most successfully recycled materials of the world. The corrugated carton boxes are not difficult to recycle.

They can be transferred to a recycling centre or can be placed into the bins located at the side of the road. The boxes are transported from here to a paper factory which processes them and converts much of them into new corrugated paper.

Summary

Hopefully, the guide answered your questions related to the corrugated carton.

However, if you have any question or you want to know whether your packaging is manufactured of the most cost-effective material, do not hesitate to contact the design engineer of Color Nyomda!

Contact us and we will find the most suitable printing solutions for you.

Display gyártás a Color Nyomdában, a Durst WT250 segítségével

-

gyors, akár 300 m2 nyomtatás óránként

- megbízható, állandó 24 órás üzemelés minimális karbantartással

- kiváló minőségű, 1000 dpi nyomtatás

- 3 fázisú szárítás a pontos és tartós nyomatokért

- a festék a SWISS Ordinance és a Nestlé élelmiszeripari tanúsítványaival rendelkezik

- környezetbarát, ECOLOGO kompatibilis, ásványi olajoktól és nehézfémektől mentes technológia